Optimize inventory and customer satisfaction

Warehouses and bins, warehouse units, lots, serial numbers, packages, labels, receipts and deliveries, movements between warehouses, inventories, stock valuation, transport, etc.

The warehouse management processes built into NEO Clouds ERP allows the inventory in your organization to always be up to date and correctly valued. The possibility of defining the warehouse structure of your organization to unit level (storage bins) facilitates the exact localization of your stock at any time. Additionally, the capacity for managing product lots and the possibility of using serial numbers assure compliance with the tracking requirements imposed by the majority of industries.

- Warehouses and storage bins (multiple warehouse use available).

- Stock products in multiple units (for example in kilograms and boxes).

- Personalized product attributes in the warehouse (color, size, quality description, etc.).

- Lot and serial numbers.

- Management of bundles in warehouses.

- Restocking control.

- Traceability configurable by product.

- Movement among warehouses.

- Picking strategies (according to stock, with rules of priority by expiry, location, etc.).

- Physical inventory. Inventory planning. Continuous inventory.

- Reports of movements, tracking, stock, arrivals/departures, expiry, inventories, locations, etc. Personalized reports.

- Integrated with NEO Clouds POS

- Synchronization and control of the stock in the shop floor

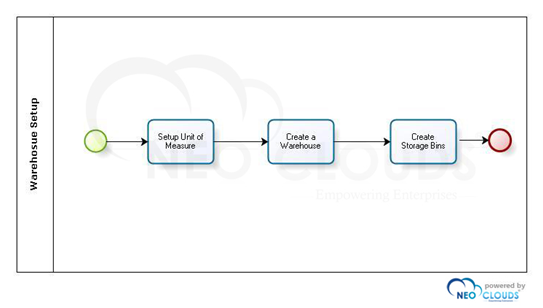

Create or Edit Warehouses or storage bins:

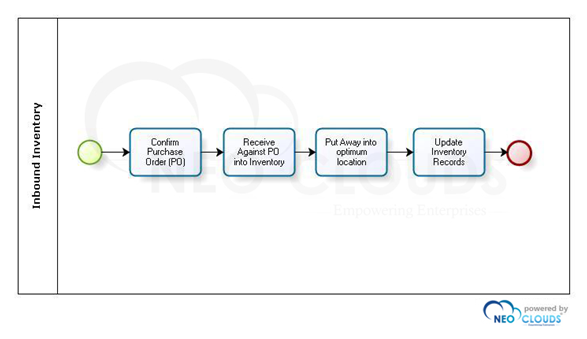

Inward Inventory Flow is explained by the following Process Diagram:

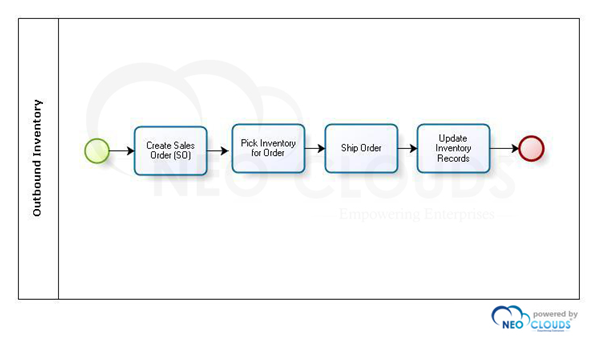

Outward Inventory Flow is explained by the following Process Diagram:

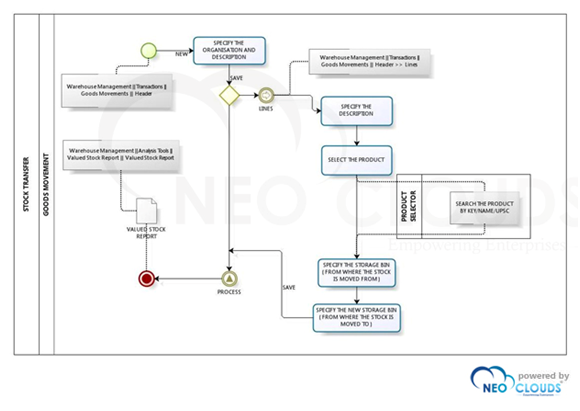

A Stock Transfers Process transfers inventory between storage bins or warehouses: